How can you succesfully implement or optimize supply chain management?

Your organization is operating in a dynamic landscape, a world that is changing faster than ever before and where customers are becoming ever-more demanding. As a company, you must continuously improve the speed, effectiveness and efficiency with which you are able to respond to those changes – so good internal and external collaboration, flexibility and a tight grip on costs and complexity are essential.

How can you turn your complex supply chain into an integral one which enables you to create sustainable competitive advantage?

Supply Chain Optimalisatie Methode van BLMC (SCOMB)

Based on our study of the academic literature, scientific research of our own and many years of practical experience, we have developed the supply chain optimization model (SCOMB) described below.

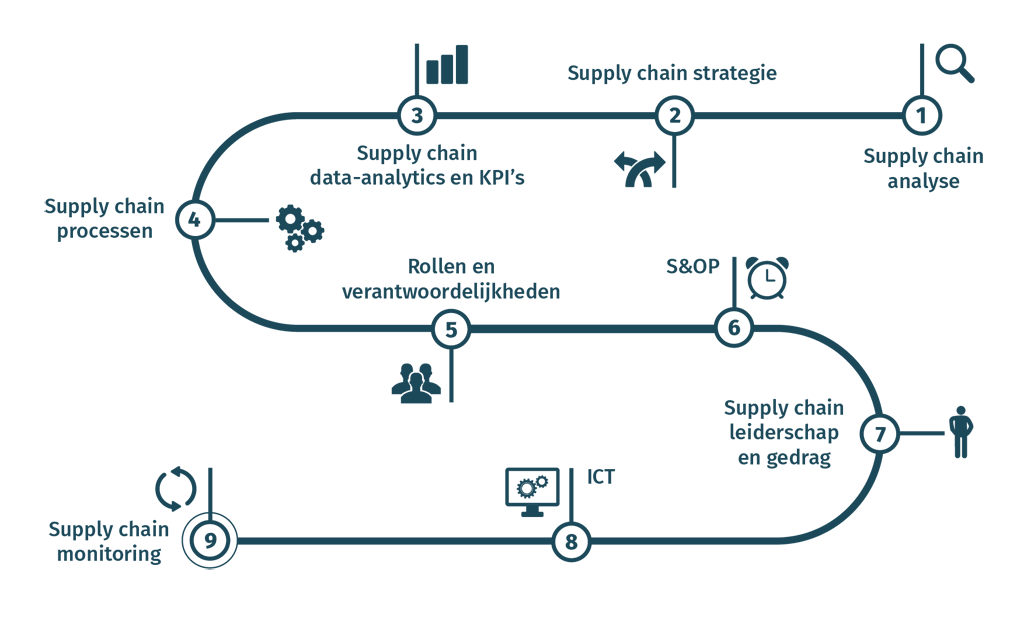

The SCOMB comprises nine modules:

Supply Chain Analysis: a benchmarking tool which enables us to assess the level of supply chain integration within your organization. Based on our findings, we work with you to identify areas for improvement and possible solutions.

- Result: the output is a detailed and context-specific step-by-step plan based on prioritized projects that will take your organization to the next level of supply chain performance.

Supply Chain Strategy: this module has two aims – better customer value and more profit. One important activity is to differentiate your supply chain based on product-market combinations (PMCs). We create the optimal balance between cash, cost and service for each PMC.

- Result: you eliminate unnecessary costs and can offer the highest possible customer value per PMC.

Supply Chain Data-Analyse & KPI’s: data analysis is necessary to identify the optimal balance between cash, cost and service for each PMC. After conducting the analysis, we assess which KPIs are relevant for each supply chain. We ensure that these KPIs are measurable.

- Result: you can make sound decisions within the supply chain triangle of service, cost and cash based on quantitative analysis.

Supply Chain Processes: we use special process analysis techniques to define these supply chain processes and link them to your strategic objectives.

- Result: conflicting interests in the supply chain are replaced by synergy and a shared goal – optimal customer service.

Roles & Responsibilities: we define the roles and responsibilities of everyone in the supply chain. This ensures close alignment and improves collaboration between the employees by providing transparency in terms of each individual’s added value.

- Result: the supply chain processes are clear, making them easy to manage and execute.

Sales & Operations Planning: connecting the (forecast) customer demand with the operational processes. S&OP not only requires good ICT support, but also depends on people’s willingness to get together and share information with one another on a regular basis.

- Result: close alignment between supply and demand, generating more profit and greater customer satisfaction at lower costs.

Leadership & behaviour: there can be conflicting interests in the supply chain. To ensure successful implementation of supply chain management, whether within or between organizations, it is very important that all the professionals involved collaborate well with one another. At every step of the supply chain optimization process, we pay just as much attention to the human factor as we do to the technical and operational factors.

- Result: you are assured of sustainable collaboration between all the professionals involved in the chain as the basis for supply chain success.

ICT: information and communication technology (ICT) systems must be put in place, derived from the supply chain strategy, processes, cross-functional teams and process-related KPIs. These systems support the optimized flows of goods, information and communication.

- Result: the improvements are anchored in your organization.

Supply Chain Monitoring the aim is to become a ‘learning organization’ that is able to adapt to market developments and changing customer needs. Therefore, an optimization project is not complete until you have determined how you can continue to measure your performance and how you can take corrective action quickly if necessary.

- Result: thanks to the Monitor, your organization can continuously adapt to the changing market enabling you to maintain your competitive edge.